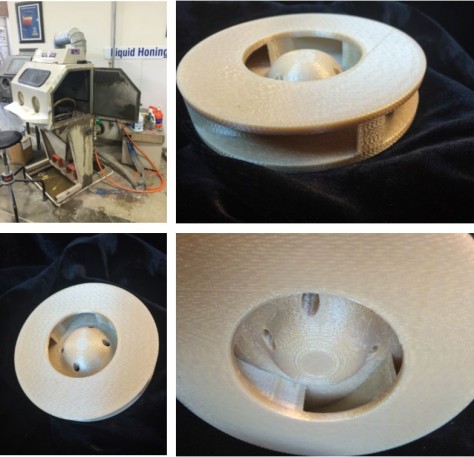

We had some room on the SLS platform so we added a few fun Valentine’s Day themed parts found on Thingiverse.

Then I found another design…

They still need some clean up, and a little color, but they will make fun key-chains.

Download the Geared Heart File Here!

Download the Celtic Clover File Here!

Hours could be spent scrolling through all the wonderful designs offered on Thingiverse. Ahem, not that I’d know that first hand or anything. 🙂

1. What are the roots of Valentine’s Day?

a. French

b. Roman

c. German

d. Native American

2. Which Pope declared Valentine’s Day a holiday?

a. Pope Francis

b. Pope Peter

c. Pope Gelasius

d. Pope Benedict IV

3. Physicians of the 1800’s commonly prescribed _________ for a broken heart.

a. Chocolate

b. Sweethearts

c. Strawberries

d. Ice cream

4. Who is Cupid’s mother?

a. Serena

b. Venus

c. Aphrodite

d. Ceres

5. Who is Cupid’s wife?

a. Psyche

b. Aurora

c. Vesta

d. Helen

6. Cupid is the God of ________?

a. Lust

b. Love

c. Hate

d. Desire

7. Who invented the first box of chocolates for Valentine’s Day?

a. Fannie May

b. Milton Hersey

c. Pete Daffin

d. Richard Cadbury

8. St. Valentine was known as a martyr for doing what?

a. Wearing his heart on his sleeve

b. Passing out scriptures, later became Valentine’s Day cards.

c. Marrying couples during times of war.

d. Being a spy for the Catholic Church.

Please send your guesses/requests for the correct matches to:

newsletter@met-l-flo.com

If you’ve got an idea for a great trivia teaser, please submit it to the email above for possible inclusion in a future addition.