Click here to view the fully formatted newsletter.

Deck the Halls

1. How many actual gifts are mentioned in the song Twelve Days of Christmas?

A. 144

B. 364

C. 155

D. 284

2. In 1836, what was the first state to officially recognize Christmas as a holiday?

A. Alabama

B. Pennsylvania

C. Virginia

D. Georgia

3. What year was the poinsettia plant brought to America from Mexico?

A. 1865

B. 1837

C. 1824

D. 1829

4. Which President was the first to decorate on official White House Christmas tree?

A. Lincoln

B. Kennedy

C. Pierce

D. Nixon

5. What state has a town named Santa Claus.

A. Illinois

B. Indiana

C. Wisconsin

D. Iowa

Please send your guesses/requests for the correct matches to:

newsletter@met-l-flo.com

If you’ve got an idea for a great trivia teaser, please submit it to the email above for possible inclusion in a future addition.

Answers from the last trivia:

Fall Fun

1. In what year did Americans celebrate two Thanksgivings? C. 1939

2. Where did Jack O’lanterns originate? C. Ireland

3. Thunder in the fall fortells what? C. Cold winter

The Casting Process

Have you ever had a project where an SLA part wouldn’t fit the bill, but you weren’t sure which direction to turn next? There are many prototyping options available beyond plastic SLAs. If you need more than one of the same part, the casting process can be an excellent alternative. Met-L-Flo casts prototype pieces in urethane, rubber and silicone. This option is offered if you need a short run for testing parts, mock fit up, marketing strategies, product development, tradeshow pieces for exploration at your booth, or even as giveaways. This process is particularly beneficial for larger quantities, typically resulting in a per part cost savings.

Example: The management team will be reviewing a new design, and you want each of the ten team members to have a prototype in their hands.

This process begins with printing the 3D data, typically in an SLA to produce a master pattern. That pattern is then molded in silicone to produce a tool that will be used to cast the desired number of parts. There are a wide variety of casting materials available to fit your project needs. The material can be run in soft durometers, or harder durometers to simulate ABS, HIPS, or Rubber. We can also create a plastic tool to produce silicone parts. These parts have options after they are cast as well. We can texturize them or paint them to give them a production look. They can be made paint ready for you to paint. If inserts are required, we can install the inserts or make sure everything is cleaned up for you to install them. Imagine, a finished part to give to your management team that they can touch, feel, and evaluate hands on.

One of our customers graciously gave us the green light to share photos of their casting project with you. This client needed something flexible to fit over their phone. After reviewing the geometry we recommended a rubber urethane. We were given the order to proceed. We made several in a soft rubber then sent them out for evaluation. After reviewing, the customer wanted something that was a bit more rigid. One of the benefits of using this process is the mold can be used with several different materials. Therefore we were able to change material durometers and meet their new expectation without needing new tooling.

Give us a call to hear about casting options that will work for you!

New Material Offering

Earlier this year, one of our customers presented us with a challenge. They not only needed fast prototypes, the parts had to meet specific critical properties to satisfy intense testing requirements. Once we took a look at the property requirements, the search began. It quickly became apparent that their target numbers for Tensile and Flexural modulus were virtually unheard of in traditional prototyping materials.

Then, Carl mentioned Windform.

Windform is a 3D printing/SLS material that blows away the competition in terms of ultimate strength per density. It’s the brainchild of CRP Technology who have been working with motorsports companies since the 1970s. Since then they’ve developed various types of Windform with Windform XT 2.0 being the most popular and “Top Level” material. It is a carbon fiber reinforced composite material. Windform has been used in industries ranging from, but not limited to aerospace, automotive, motorsport, and UAV. For Met-L-Flo, Windform is a great option when a client needs production grade strength or better in a matter of days.

Here is a snapshot of Windform properties compared to other materials:

Surviving The Holidays

1. Set a realistic budget:

Set a realistic holiday budget for gift giving. Presents do not have to be so costly that will break the bank. If you have a large family, drawing names for gift buying will reduce your cost and stress level.

2. The season of giving:

Volunteering time and/or donating items to charities is really rewarding. There are many food pantries that can use the help during the holidays (and all year long) ranging from food donation, to food prepping, to serving the food. Volunteering and donating is great for all ages. Get your little ones involved by donating last year’s toys to make room for the new toys that Santa will bring this year. There are many organizations that need volunteers such as Toys for Tots, Salvation Army Gift Giving, also many local fire/police stations donate gifts and will need presents wrapped.

3. Enjoy the spirit of the holidays:

After dinner load the family in the car and take a drive around your neighbor to look at the pretty lights your neighbors are displaying. While in the car you can play holiday music to enhance the experience. Spending quality time with the family can help you relax and enjoy the season. Remember it’s the little things in life.

4. Plan ahead:

Make a plan and try to stick to it. (Make sure to have plans B & C just in case)Set goals that are realistic for accomplishing tasks leading up to the big day. Spread the tasks over a few weeks, so you do not get overwhelmed.

5. Continue your daily routine:

Do not stop your overall normal routine.Continue to work out, sleep, take your vitamins, and eat healthy. This allows your body to function properly and have the energy to complete the extra tasks. It also helps keep you from over indulging at all those holiday gatherings.

6. Breathe:

Remember this time of year is about spending quality time with your family and friends. When things start to get stressful take a deep breath and remember what’s most important, you’re together!

From our Met-L-Flo family to yours, Happy Holidays!!

Benefits of Using Service Bureaus

As we all know, high end appliances are becoming more popular in our homes and as the housing market begins to turn around home owners will be requiring even more high end products. The big question for manufacturers always remains… how do we know the product is what the customer wants before going to manufacturing? In an effort to answer this question, appliance manufacturers analyze feedback gathered from market studies and consumer reviews. However, it is very expensive to produce a new refrigerator, dishwasher, stove, etc., each time they conduct a new product focus study. The most logical answer: prototyping. The majority of new appliance prototypes will require a large range of plastic parts that include, water clear parts (i.e. produce bins), parts with a metallic finish (i.e. door handles), and parts with specific paint colors (i.e. interior frame parts).

Since design centers are limited in the variety of parts they are able to produce, the manufacturer’s best choice becomes outsourcing to Met-L-Flo. We offer an extensive array of processes and finishes to satisfy a wide range of part specific requirements—water clear SLAs, polypro & ABS-like SLAs, SLS, FDM (parts out of ABS, PC, Ultem, PPSF & Nylon), and traditional casting & rotomolding with a range of materials, colors and textures to match injection or blow molded parts.

Real World Applications of 3D Printing

As one would expect—day in and day out—use of equipment takes its toll. Preventative maintenance programs are a must, but at the end of the day… sometimes things just break.

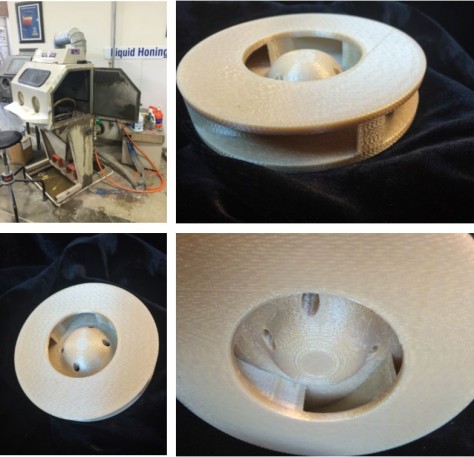

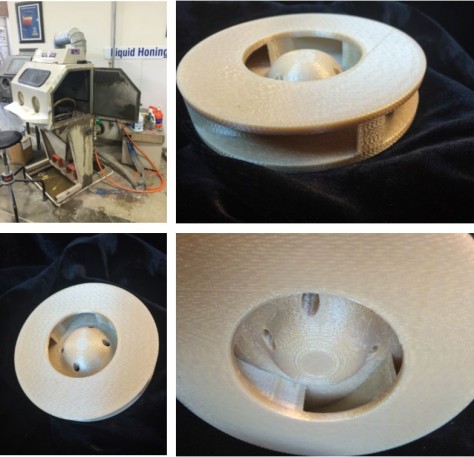

Recently, our liquid honing machine, started acting up. A honing machine looks a lot like a sand blast cabinet, but works through a combination of air pressure and water solution pressure. Great for plastics, this action is gentle and works well to clean up rough edges and leaves a nice consistent finish surface appearance.

Unfortunately, our honer was not functioning properly. At first we believed the air pressure was the culprit. However, after disassembly of the inbound air line, it was determined that the foot activated electrical solenoid which allows air passage was bad. The rubber diaphragm inside the solenoid had deteriorated from age. We got on the horn with the honer’s manufacturer in search of the solenoid. They located a solenoid for us and overnighted the piece. We received and immediately installed the part. The results were better, but still not 100%.

We moved to the water pressure side of the equation. The inbound water is supplied via a regular hook-up similar to that on your washing machine. However, that water is constantly regurgitated in the bottom hopper to ensure water and cutting media are mixed. The process is driven by an electric motor and a mechanical water pump. The inconsistent “surface appearance” of our parts lead us to believe the water pump was not performing its job. After disconnecting the water, air and electric, we began to disassemble the water pump. In short order, we identified the pump impeller had broken off the main shaft. Back on the horn with the manufacturer. The new complication became a 2 to 3 month wait for the new impeller—not an option. The honer is used several hours daily. One of the things I believe we do well at Met-L-Flo is find internal solutions. We decided to build our own impeller! Why not… it’s made out of plastic. With some estimated measurements and a little CAD magic, we were able to reverse engineer the part. Once we had the CAD, we were ready to build. We decided to build the part in our FDM (Fused Deposition Modeling) machine for strength and durability.

While the part was being built, we cleaned up the pump body and chased all threads to insure an easy re-assembly with all new stainless steel hardware. Reassembly is now done and it’s time to test….

The results are excellent!

We can once again provide our customers with the quality parts that we are committed to deliver…

President’s Message by Carl Dekker

We continue to see much advancement in the materials and equipment offered in the Additive Manufacturing/3D Printing space. The press is filled with new materials appearing regularly for many different technologies. Although not as sexy, there are also many usefully developments in the secondary tooling technologies. All of this progress combined with advanced applications continues to make every day an enjoyable challenge in this ever changing industry.

Above you’ll find, or already enjoyed, an article about applying Additive technologies to resolve an internal maintenance issue. Our production floor brought us the internal solution when the lead time for the replacement part was deemed unacceptable. Extensive training empowers our staff to identify and support the best solutions for our internal production needs, as well as, identifying our client’s and partner’s challenges. The more we understand about our partner’s needs, the more capable we are of implementing the best technology options. The implementation of today’s technologies builds the foundation for tomorrow’s solutions. We look forward to creating tomorrow’s solutions with all of our partners.

Finally, as you work hard to wrap up end of the year projects, remember to take some time to recharge and reflect on the past year. Please allow me a moment to extend my appreciation for the opportunity to work with each of you through the year. I wish you safe travels over the holidays as well as fun and relaxation with loved ones. We look forward to working with you in 2015!

========================================================== Copyright © 2014 Met-L-Flo, Inc., All rights reserved. Newsletter Our mailing address is: 720 Heartland Drive, Unit S Sugar Grove, IL 60554